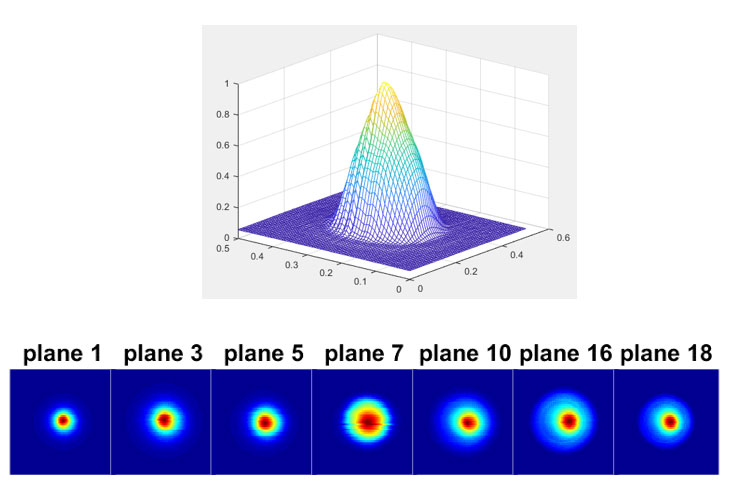

FL Series Beam profile

*Gaussian beam

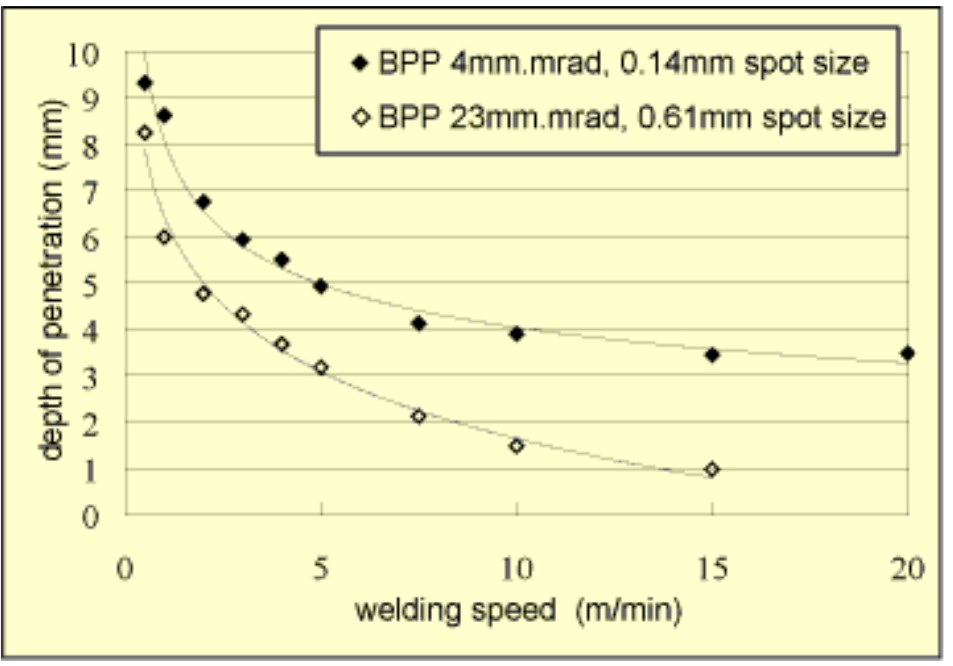

- The best BPP in the world <1.5 mm*mrad

- Commonly used for thin plate cutting, fly cutting and remote cutting or welding.

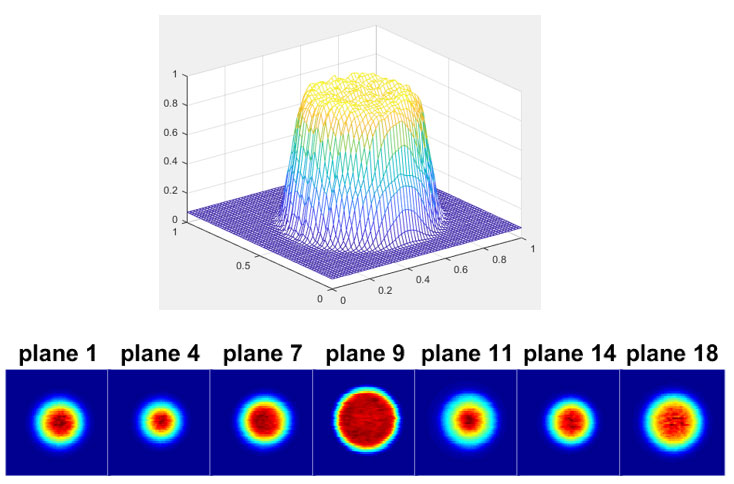

FT Series Beam profile

Flat-top beam

- BPP < 7 mm·mrad

- Great solution for thick plate cutting, welding, and heat treatment.